It’s no secret that pipe inspection isn’t the cleanest job in the world. Nor is it the safest. Let’s look at Pipe Inspection Robots Everything You Need to Know.

As an inspector, you’re often working in conditions that are less than pleasant. Many of your workspaces are dark, hot, and more than a little cramped.

Thankfully, there are modern tools and technologies that are designed to make your job a little easier.

Enter, pipe inspection robots.

While their name might sound like something out of The Jetsons, these handy devices are real and revolutionary. They’re also changing the pipeline industry for the better. Designed to get the job done while keeping workers safe, these robots are helping to alleviate the legwork and dirty work involved in the pipe inspection process, along with much of the risk.

Today, we’re taking a closer look at how they work and their many applications.

Ready to learn more? Let’s get started.

What Are Pipe Inspection Robots?

Inspecting a pipeline often requires actively crawling into the pipe to detect the damage. We don’t need to explain why this step is inherently dangerous on many levels.

One recent study followed millions of miles of pipeline in the United States for nearly nine years. The findings?

There were more than 5,500 total pipeline-related incidents during that time. In addition, there were nearly 600 injuries and more than 125 fatalities. With more than 800 fires and almost 300 explosions, the study revealed the always-present dangers that pipe inspectors face on a daily basis.

The idea for pipe inspection robots was born in response to this threat.

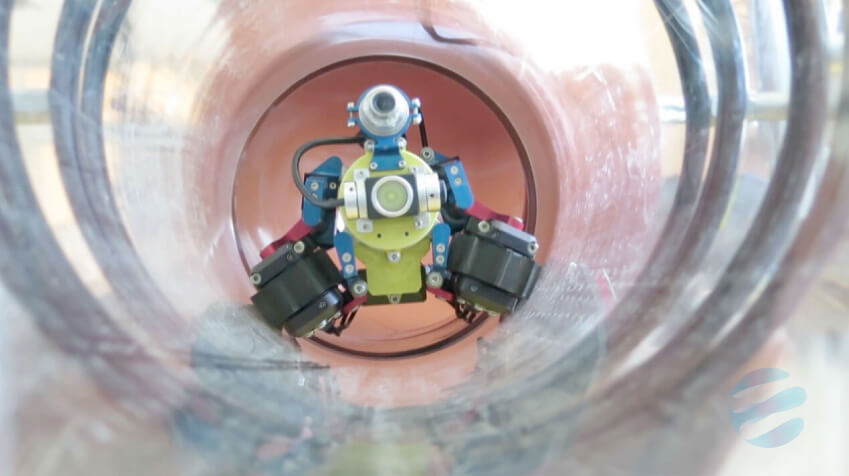

These are small, battery-operated CCTV pipe inspection robots that can essentially take on the mind and function of a human employee. Fully submersible and easy to control, they can travel deep into even the longest pipelines, helping teams uncover hidden issues without putting themselves directly in the line of danger.

Advantages over Human Inspection

We’ve already covered the fact that pipe inspection robots make the job safer for employees by diving headfirst into conditions that could otherwise be perilous for human employees.

Yet, this is only one of the reasons why it’s smart to invest in a system for your team. Let’s explore a few of the others.

Longer Inspection Duration

The longer a human inspector stays inside the danger zone trying to find a new pipeline issue or inspect a known one, the greater the risk of injury. On the other hand, a CCTV crawler robot can stay inside of the pipeline for a much longer duration of time without facing additional risk.

Meanwhile, a human inspector can stay safely above ground, monitoring and controlling its actions accordingly.

Quicker Inspections and Pipeline Repairs

Once the robot discovers the problem, the workers know exactly where to start working. This means they don’t have to spend extra time investigating the issue or looking for the compromised areas. They can also skip the time they used to spend waiting for jet or pump trucks.

Even setup times shorten, as most CCTV pipe crawlers are deployable from anywhere, allowing inspectors to investigate municipal wastewater and storm pipes within a few minutes. There is no clunky equipment to unpack, topside power or boxes to contend with, or time-consuming assembly to complete.

In fact, the entire system fits into two portable, compact carrying cases with ease. Battery-operated, the robot even eliminates the need for a CCTV truck, generator or onsite power supply.

When they’re able to begin repairs as quickly as possible, job completion times shorten and teams become more productive. In today’s fast-paced environment, any measure you can take to save time and improve output is a valuable one.

Flexible Deployments

Until recently, pipe inspection robots were rudimentary at best. Compared to the sleek models available today, early ones were much larger and cumbersome to handle. They also required special transportation vehicles to move them between job sites.

The result? They were used less frequently and pipelines went uninspected.

They’re also adaptable to fit a range of working conditions, including pipes as narrow as six inches in diameter and as large as 36 inches in diameter. They’re also fully waterproof and can travel as deep as up to 50 meters (164 feet) underwater! In addition, you can also deploy them inside of a range of pipeline materials, including:

- PVC

- Brick

- Clay

- Concrete

- High-density polyethylene (HDPE)

- Corrugated steel

- Cast iron

This means you can take your robot with you on nearly any job, confident that it will accommodate the environment and conditions you’re working in. This makes it possible to achieve more frequent inspections without the stress and headache that former systems presented.

Looking for extra flexibility? You can even use the integrated quick-release brackets to swap the position of the compact camera. If you need to move it from the vehicle to the elevating arm (or vice versa), the swap takes mere seconds.

Working on terrain that’s especially rough and rocky? You can upfit our CCTV pipe crawlers on the job site by quickly adding larger wheels or tracks so the robot can travel around smoothly. This means there’s no job that your inspection team can’t tackle!

Add-On Equipment

We understand that as an inspector, you often come across pipe profiles that are vastly different from one another. As such, you need an inspection system that can adapt to a range of conditions.

That’s why we developed our pipe crawlers to be modular in nature, featuring plug-and-play technology that helps them accommodate a range of add-on equipment, including:

- Digital video glasses

- Special wheel kits

- Digital video recorders

- Grit wheels

- Elevating arm

- Microphones

- Rear-facing cameras

- Spacer kits

- Many more

You can view our full line of equipment here.

Remote User Control

Rather than heading into the pipes themselves, inspectors can manage the entire robotic system from a lightweight, handheld all-in-one control system. With the controller in hand, they can view the real-time, live video feed that the crawler’s high-definition camera provides.

To achieve a clearer view, users can adjust the shadowless LED lighting from directly behind the controller. This can help them improve visibility and brightness in even the darkest conditions. They can also take a closer look at any imperfections and other issues via the camera’s pan, tilt and zoom features.

This connection is made possible via a thin, durable tether that connects the robot to the controller. Once the appropriate videos and images are captured, users can document the inspection and upload all of the findings directly to an integrated asset management software.

Change the Way You Look at Pipe Inspection

Are you ready to transform the way you do your job?

As a pipe inspector, you hold one of the most important and critical positions in your community. Yet, that doesn’t mean you have to suffer through miserable or unsafe working conditions.

Pipe inspection robots are here to stay, and embracing this technology could take the strain off your shoulders and the worry out of your mind. Our MDB Marine pipe crawlers are industry disruptors, recognized as the first truly portable, battery-operated systems of their kind.