MDB Marine’s path to ISO certification was something we knew we had to achieve if we were to stand out from the rest. As with all companies, we have to abide and follow certain guidelines to compete with the global companies. Having certifications by governing bodies sets a standard that potential clients can then trust.

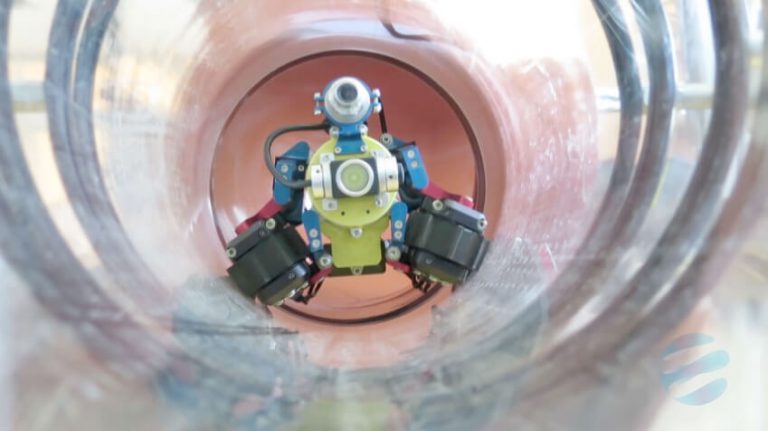

When MDB Marine began operating, we were already proficient in Remote Operated Vehicle (ROV) operations, had a list of clients who wished to use our services locally and a growing list of people interested in the basic services we had to offer at the time. Back then, simple operating and health and safety procedures and were all that we used to satisfy the requirements of our small, 2 man company based off of small, local work scopes.

As we developed and various opportunities arose, we realised that accredited work scopes were required by clients in the Energy and Maritime sector and our route to be considered for those type of work scopes was to gain the accreditations. Firstly in 2017, we gained ISO 9001 (2015) which was the underpinning accreditation required to demonstrate our adherence to quality management and gain further industry accreditation. This was a very proud moment for a fledgling company such as ours.

In 2018, aiming to complete water ballast tank inspections using ROV, we gained DNV, Thickness Measurement on Ships accreditation. At the time, there was no facility within IACS for remote inspection techniques (RIT) of water ballast tanks and that method was used on a case by case basis, with agreement between the Service Supplier, the Duty Holder and the Independent Competent Person representing the regulator. The main accreditation we required at that time was Thickness Measurement.

Fast forward 2 years and we were well under way in our development and throughout 2020. We worked tirelessly in research and development and procedural compliance investing in the tools, training and equipment needed to complete In Water Surveys in leu of Dry Dock (UWILD), Mooring Chain assessment utilising Remote Inspection Techniques (including accurate and repeatable measurement of mooring chains) and Remote Inspection Techniques (RIT), which was now adopted by IACS as an industry standard.

In 2021, we were elated to be awarded with the accreditations we spend 18 months in development attaining. We now held Remote Inspection Techniques, In Water Survey and Mooring Chain assessment on top of our Thickness Measurement on Ships accreditation.

Our most recent set of accreditations came about off of the back of an Achilles FPAL verification audit where we were marked lower than we had hoped on our Environmental and Safety Management sections. Even though we had zero accidents or environmental incidents, there was areas where we could improve and as a company that always looks forwards, towards improvement, we set to the task of gaining ISO 14001 and ISO 45001 and implementing further robust controls that enable us to be seen as an organisation that is on a quest to comply with the most fastidious of industry standards.

We were able to meet the standards of these accreditations in 2022 having implemented a new Integrated Management System (IMS) incorporating these new standards and the controls within them. Another proud moment in our development.

Looking forward, MDB Marine will continue in this progressive manner, watching the industry in which we work closely and improving our services and the manner in which we conduct our business. We’re particularly pleased to have done this as an organically grown business, having taken no capital investment but built ourselves off of the products of our work.

See our post on linkedin here