Safe and efficient vessels are imperative for the overall success of any maritime industry, Optimizing Vessel Performance with ROVs work happens below the surface where there are limited options for getting a visual on what is going on. With an ROV , operators can get eyes underwater exactly when and where they need them.

Protecting the integrity of a vessels hull is extremely important in order to keep it at peak performance. In addition to negatively impacting speed and fuel efficiency, a damaged hull can cause serious issues to the vessel, crew, cargo, and surrounding marine life.

While regular hull inspections are a necessity for optimal vessel performance they can be difficult. In addition to being expensive, dry docking takes ships out of commission for extended periods of time. Hiring divers not only requires time and money, but also potentially puts people into dangerous situations.

With ROVs providing an efficient method of hull inspection, vessels can be consistently monitored to optimize maintenance schedules and maximize performance.

What is an ROV?

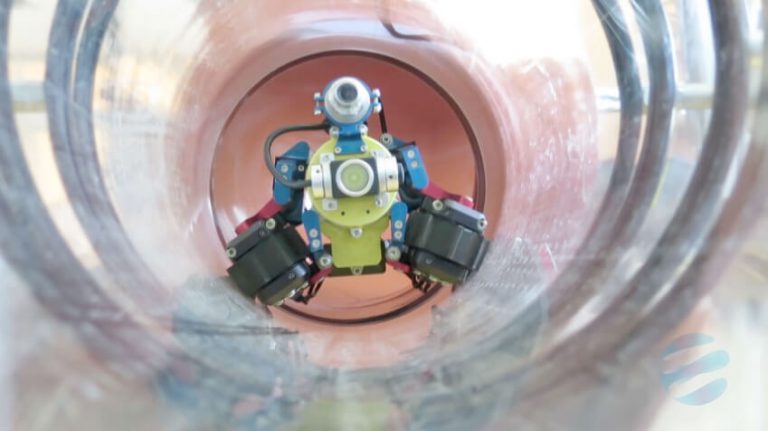

Remotely Operated Vehicles (ROVs) are unoccupied, highly maneuverable underwater robots that can be used to explore submerged worlds while being operated by a person at topside.

MDB Marine offers four models of ROVs, VideoRay Pro 4, Outland 2000, Saab Falcon and the Magnetic Crawler.

The VideoRay Pro4 is a versatile hand launchable ROV. Due to its agility and size, it is able to get up close and personal, where other types of ROV’s would struggle. The camera captures high-definition footage giving the client clear and detailed footage.

The Outland 2000 is a high-performance inspection/work class ROV with 5 thrusters it gives the ROV the power it needs to carry out the required tasks.

It has the ability to carry out cleaning by attaching a lance and hose, which is attached to a power washer kept onboard. It is also the ROV of choice for photogrammetry measurements due to its size.

The Saab Falcon with five powerful thrusters, it provides precise control and the ability to be stable and stay on location in strong currents.

It can be held in place, once at worksite, with its integrated depth gauge and heading software.

This being the largest of our fleet, the Falcon is used as an inspection / work class vehicle.

Benefits of Remotely Operated Vehicle Use for Inspection

The use of ROVs for vessel inspection are numerous. Providing benefits in regards to safety, costings and efficiency, the use of ROVs for vessel inspection has proven to be advantageous.

The primary benefit of ROV use for inspection is keeping human divers out of the water. By using an ROV in lieu of divers, people are kept out of potentially dangerous scenarios. An ROV is able to be driven into confined and hazardous situations that it would be prudent for a human to avoid going into. Human safety is a chief benefit to ROV use for vessel inspection.

An additional key benefit of ROV use for vessel inspection is the financial efficiency of an ROV when compared to alternative methods. With an ROV, dive teams do not need to be hired to conduct inspection. Furthermore, dry docking can be seriously reduced allowing for additional financial savings. Finally, the ease in which inspections can be conducted allow for operators to catch minor issues before they become large and expensive problems. With an ROV, maritime teams have the ability to reduce their spending significantly.

Relating to the financial efficiency of ROV use for vessel inspection is the ability to save significant amounts of time through the use of an ROV. By using an ROV for hull inspections, clients do not have to wait for scheduled DSV’s to be available and to arrive. Moreover, inspections can be conducted in a convenient and timely fashion with the use of our ROV’s, which are hand launchable from the asset.

Vessel Operations Optimization

Through ROV inspection maritime teams can optimize vessel operation. The consistency of inspection made possible by ROVs allows for frequent updates in regards to the state of a ship’s hull. By staying on top of inspections, operators can make well-informed decisions regarding repairs, coatings, dry docking schedules, etc.

With ROVs providing an efficient method of hull inspection, vessels can be consistently monitored to optimize maintenance schedules and maximize performance.

Conclusion

The use of ROVs has been proven to optimize vessel performance. By providing operators with a reliable and convenient manner in which to conduct hull inspections, inspections can be done regularly to ensure the structural integrity of the hull. In addition to catching minor issues early, with frequent inspections operators have the data they need to make informed decisions regarding repairs and shipping schedules. Furthermore, the use of ROVs for vessel inspection keeps human divers out of harm’s way in a quick and financially efficient manner.

To learn about real life examples of the ROVs in action, check out our video page here. Our industry experts are here to answer your questions, contact us today!